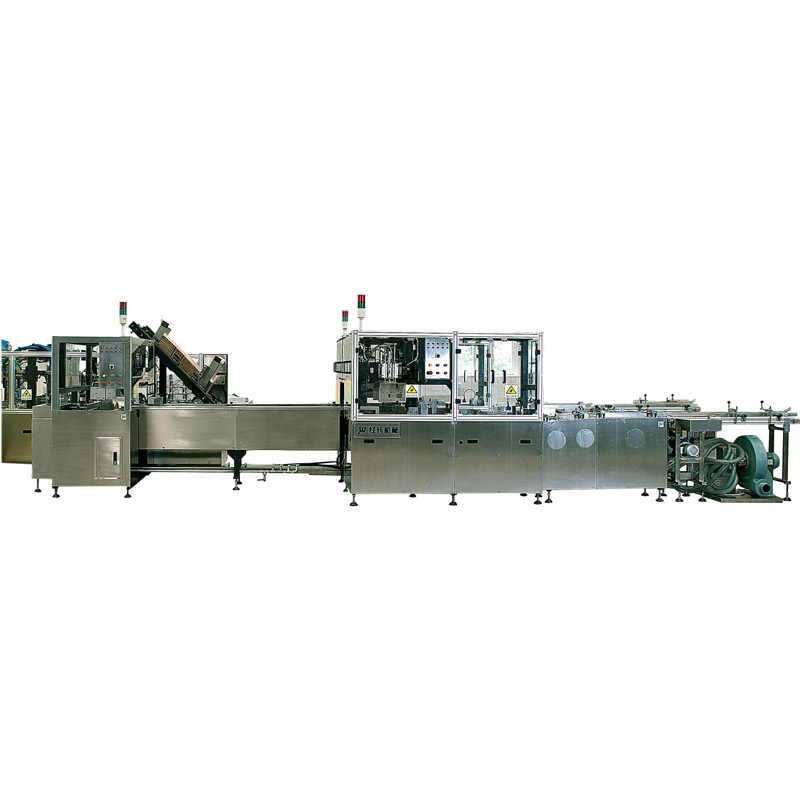

Bag Noodle Case Packer-ZJ-QZJ20

| Ƙarfin samarwa | 18 lokuta/min (hanyoyi 24) |

| Tasha | Tashar ɗaki: 11;Tsayin tashar: 571.5 mm, Tashar jigilar kaya: 16;Tsawon tashar: 533.4 mm |

| Girman akwatin | L: 320-450mm, W: 320-380mm, H: 100-160mm |

| Manna narkewa ikon | 5KW |

| Ƙarfi | 15kw, uku-lokaci biyar layi, AC380V, 50HZ |

| Matse iska | 0.4-0.6Mpa, 700NL/min (max) |

| Girman inji | (L)10500mm x(W)3200mm x(H)2000mm |

| Tsayin fitar da kwali | 800mm ± 50mm |

Siffofin

1. Ayyuka masu dacewa, gudanarwa, rage yawan ma'aikata da ƙarfin aiki, da inganta ingantaccen aiki.

2. Injin yana tare da tsayayye kuma abin dogaro yana gudana, shirye-shirye na atomatik a cikin tsari da cikakkiyar rufe kwali da fasalulluka masu fa'ida.

3. Ya dace musamman don daidaitawa tare da layin taro na marufi don gane cikakken samarwa da marufi ta atomatik.

Ya dace da jigilar atomatik na noodles da noodles nan take.

Ga wasu ayyuka don fahimta:

Ciyar da Jaka: Wannan shine wurin farawa na injin inda ake loda buhunan noodles akan na'urar jigilar abinci.Yawancin lokaci ana cika jakunkuna da noodles kuma an rufe su.

Buɗe Jaka: Daga nan ana buɗe jakunkuna ta hanyar amfani da buhun buhu mai amfani da kofunan tsotsa don riƙe jakar a buɗe ta, ta ba da dama ga noodles ɗin su fita.

Gindin Kartin: Daga nan sai injin ya kafa kwali da saita su don cikawa.Katunan galibi ana cika su ne kafin a loda su cikin injin.

Cikewa: Ana cika buhunan noodles ɗin da aka buɗe a cikin kwali ta amfani da tsarin cikawa.Tsarin yana amfani da jerin bel, mazugi, da chutes don jagorantar noodles cikin kwali.

Rufe Carton: Da zarar an cika kwalayen, ana naɗe su ƙasa

Isar da Carton: Sannan ana isar da katunan zuwa tashar ta gaba don ci gaba da sarrafawa.

Ingancin Inganci: A wannan matakin, ana duba akwatunan don hatimin da ya dace da madaidaicin nauyin noodle.

Stacking Carton: Cikakkun kwalayen da aka rufe ana jera su akan pallets a shirye-shiryen jigilar kaya.

Tsarin Sarrafa: Dukkanin tsarin ana sarrafa shi ta hanyar mai sarrafa dabaru (PLC), wanda ke sa ido da sarrafa sassa daban-daban na injin.

Gabaɗaya, na'ura mai ɗaukar hoto ta atomatik buhun kwandon kwandon kwalliya hanya ce mai inganci kuma amintacciyar hanya don haɗa buhunan noodles cikin kwali.Na'urar tana iya ɗaukar babban ƙarar noodles kuma tana iya tattara su cikin sauri da daidai.Yana da mahimmancin kayan aiki ga masana'antun abinci waɗanda ke buƙatar haɗa kayan aikin su cikin farashi mai inganci da inganci.